Trend is the friend of the fashion industry for a very long time. When apparel is taken into consideration, special occasion apparels change from time to time, setting the tone of fashion and creating the trend among children, men and women of different age groups. Textile industry supports the needs of regular garments.

Trend is the friend of the fashion industry for a very long time. When apparel is taken into consideration, special occasion apparels change from time to time, setting the tone of fashion and creating the trend among children, men and women of different age groups. Textile industry supports the needs of regular garments.

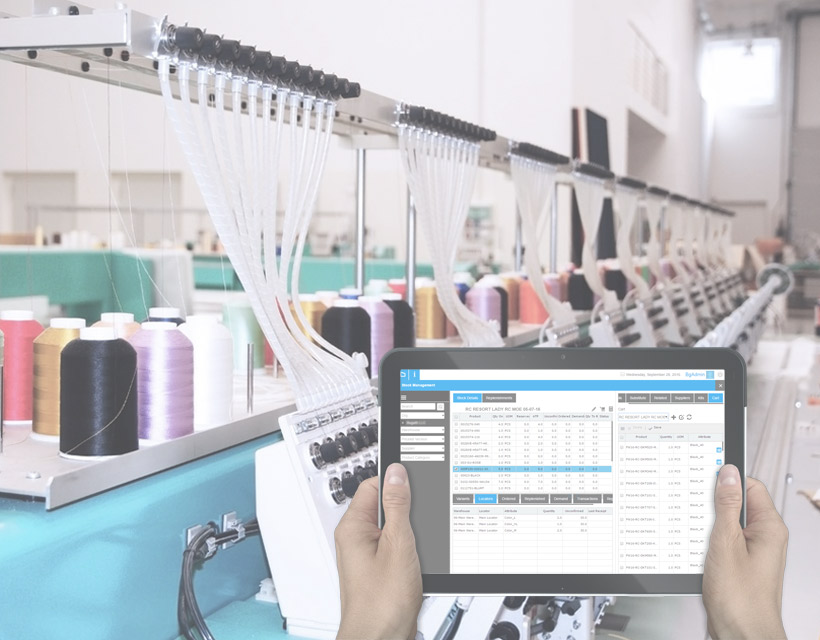

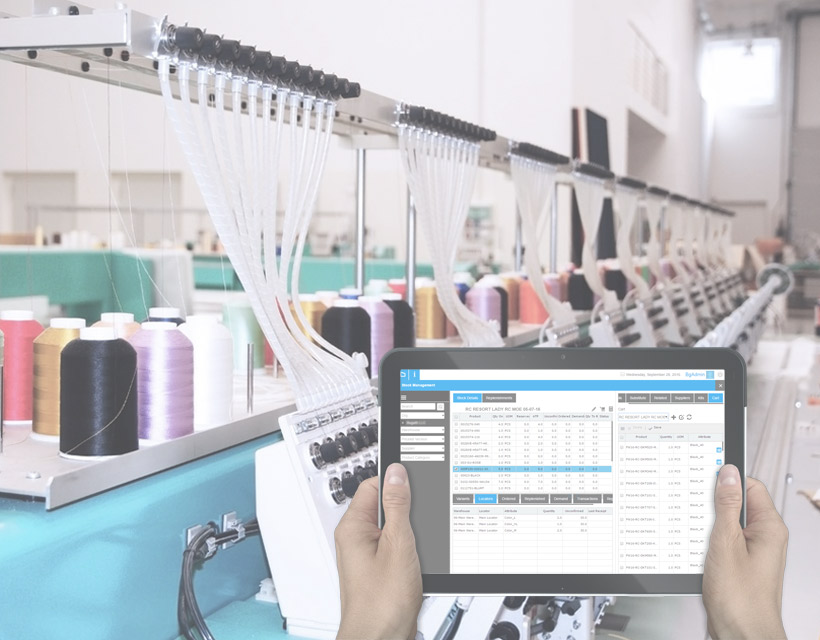

For whatever be the needs – occasional or common, production figures of garments should be more than that of the demand figures. The designing and manufacturing of apparels are rested to the textile industry whereupon distribution and selling happens. For keeping pace with the demands, textile industry at present has incorporated inventory software like the Enterprise Resource Planning (ERP) software. It has become one useful part of the apparel and textile industry due to the benefits it presents.

ERP implementation starts from planning of production and ends at product distribution. The process of each step involved has to be mistake-free for reaching ideal profit margins. In common terms, an ERP manufacturing software has the ability to efficiently perform tasks of the textile industry without involving any complicated step. Therefore investment in correct form of ERP is truly valuable for apparel business owners.

Uses of ERP Software

ERP software is used in managing business processes in a systematic manner. The administration and management of any apparel business at every operational level like planning, development, manufacturing, distribution and selling are able to manage the business at their convenience without any disruption. ERP software records down the available resources or raw materials and keeps information about the previous production, distribution and sales. Businesses of any scale can use ERP software and customize the software for particular business demands. It is a prime advantage of using ERP software. Divisions, where ERP software in an apparel company can be implemented, include the company’s HR, customer relations, finance, legal section, accounting and payroll generation.

Benefits of Using ERP Software

- Raw Material Quality Control – Raw materials are the primary inclusion for manufacturing for which quality should be maintained. Otherwise, it will adversely affect the whole production. ERP software for the textile industry is used for controlling the quality of the textile. There are options to check the raw materials are of desired quality or not. If only raw materials get approved by ERP software then only further steps are carried out. Raw materials getting ERP approval are then passed through production stages like stitching, dyeing, printing, labeling and packing. All the steps are monitored using ERP software.

- Production and inventory arrangement – ERP software helps in presetting the production steps in a hierarchical manner. If production is performed at various locations then these are linked by means of ERP software. Perfectly arranged inventory is one of the biggest assets for any manufacturing industry. Methodical inventory management is done by ERP software where options for delivery management, sell figures and stock transfers are there to help out apparel business owners. Barcoded products are easy to track with ERP software.

- Products’ Scrapping – ERP software makes sure that scraps are never mixed with regular stock. It helps in avoiding dangerous distribution problems.

- Production being not Overflow or Underflow – Production has to sync with the consumer demands. In order to maintain this strategy, ERP software gives the master production schedule option. Using the master production schedule, the balance between purchase and production is maintained. This option predicts the consumer needs for giving assurance to software planned production. Production accuracy is also increased, thus ensuring neither overflow nor underflow takes place in apparel manufacturing.

- Production Surveillance – Just by assigning serial numbers to the products, owners can keep track of the details like stock, buyers and products. This facility known as traceability feature in ERP software for the textile industry keeps product movement safe. Tags, barcodes and product labels all help in production surveillance.

- Stock Removal Plan – Stock removal plans are interlinked with product movement. If a product is to be moved, ERP software checks the availability of the product and calculates the number of products that can be allotted to shipment. Removal strategy helps ERP software in doing so. At textile industry, ERP software works with perishable goods to clear old stocks in advance to arrival of new stocks for avoiding stocking of outdated products.

- Customer Satisfaction – No doubt textile manufacturing industry faces tough competition. With innovations taking place in every firm competition has got stiffer. So sales achievement is done through strong customer relationship management. ERP software has made sure of strong sales, subtle marketing and effective communication with customers are done at all time.

- Human Resource Management – In maintaining work quality which is actually very important, human resource management options of ERP systems are implemented for maintaining work quality and germinating out the best productive works from the human resource. ERP HRM option for textile industry helps in this.

- ERP in Business Intelligence – In-depth analysis of business done through ERP software. Business Intelligence step is important for development and business profit margins. It is implemented by analyzing the performance of work centers and production.

- Invoice and Report Generation – ERP system’s invoice generation option saves a lot of time. This system is able to integrate with shipping and order entries to minimize work stress. ERP softwares’s report generation system helps in generating reports on sales, production ad and work done.

Trend is the friend of the fashion industry for a very long time. When apparel is taken into consideration, special occasion apparels change from time to time, setting the tone of fashion and creating the trend among children, men and women of different age groups. Textile industry supports the needs of regular garments.

Trend is the friend of the fashion industry for a very long time. When apparel is taken into consideration, special occasion apparels change from time to time, setting the tone of fashion and creating the trend among children, men and women of different age groups. Textile industry supports the needs of regular garments.